KRUPP Centrifuge

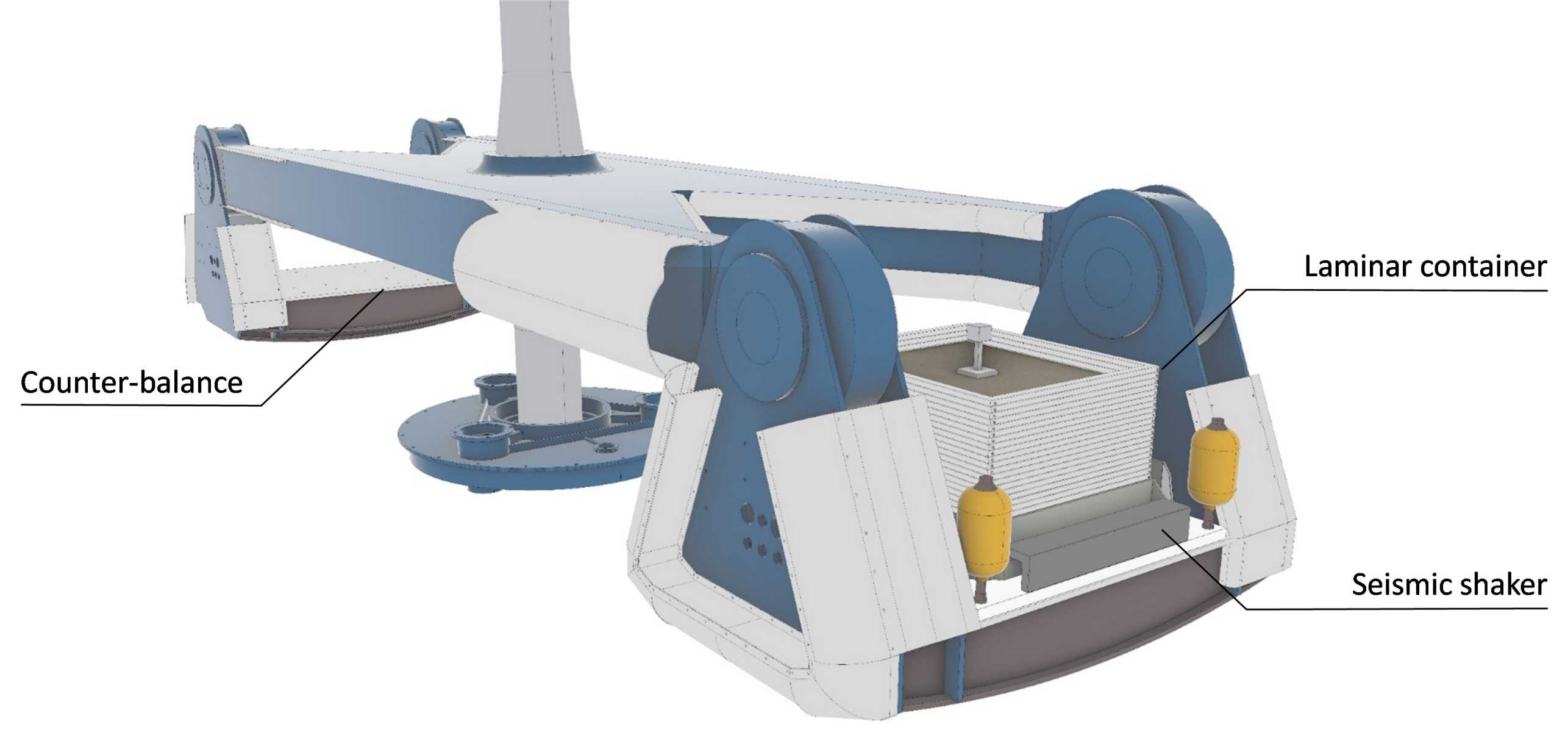

The beam centrifuge consists of an arm supporting two swings, in which the model and the counterweight are placed. It is connected to the chamber with a bottom and a top bearing, ensuring higher stability of operation. The centrifuge is not brand new, but rather an example of how existing equipment can be reused for research. The centrifuge was constructed by KRUPP and was originally installed in RUHR University Bochum, were it was under operation for over 20 years. Decommissioned in Germany, it was acquired by ETHZ and has been fully refurbished in terms of hydraulics, electronics and control systems.

With an effective diameter of 8.25 m, the centrifuge can be accelerated up to 250g carrying a payload of 2 tons (or equivalently 5tons at 100g). Its 500gton capacity is the largest in Europe and one of the biggest in the world. A key advantage of the beam centrifuge is that the model can be installed without 90o rotation (as in the drum centrifuge), thanks to the swing which rotates progressively with the increase of the g-level. As a result, the model base is always perpendicular to the acceleration vector. Each swing has a platform of 1.25 x 1.25 m, where the soil container is placed. The setup offers the possibility of a soil container of up to 2 m length (extending 0.375 m from the platform on each side), allowing testing large models corresponding to up to 500 m length (at the maximum g level).