Drum Centrifuge

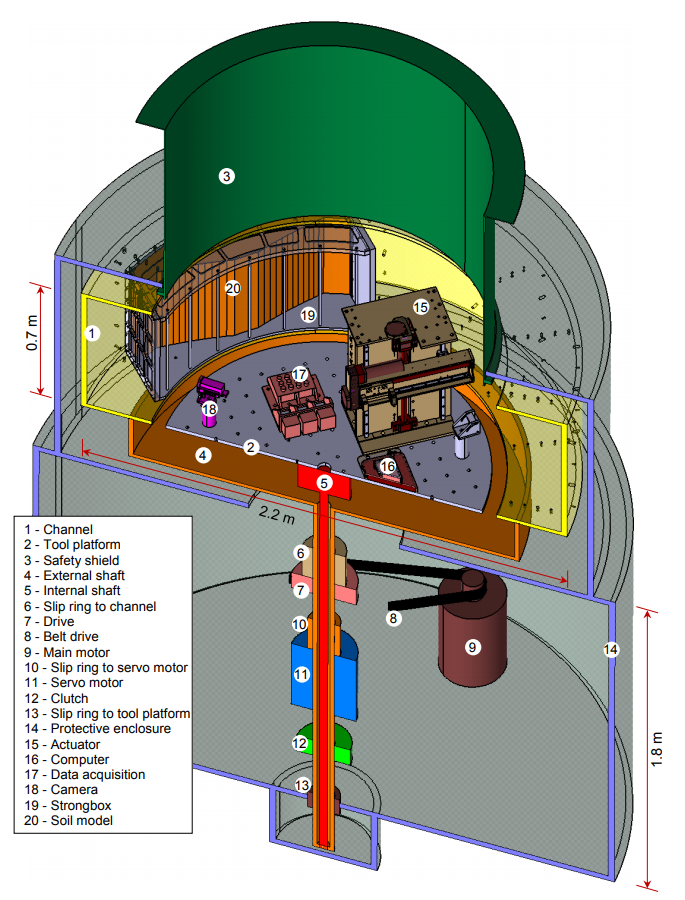

Established by Prof. Sarah Springman in 1999, the geotechnical drum centrifuge facility consists of a preparation laboratory, the centrifuge pit, and a control room, from which the technician, the project engineer and the proof engineer supervise the progress of the test (external page Springman et al. 2001). These three roles are based on the security guidelines at Cambridge University (Schofield, 1980) to ensure safe operation of the facility.

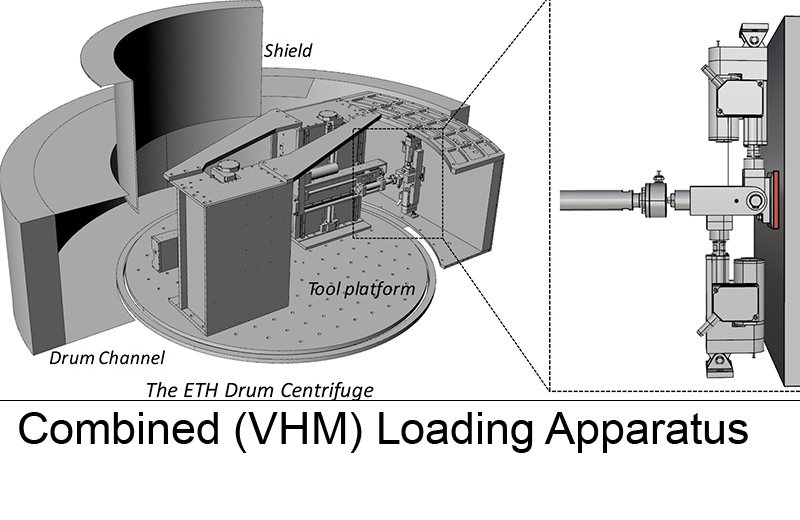

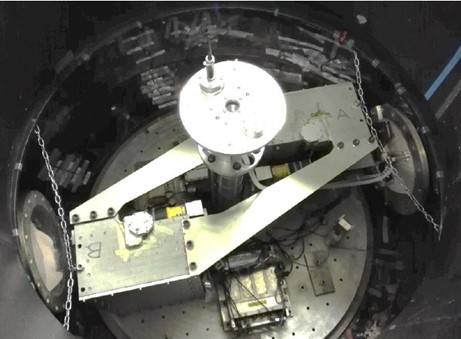

The drum centrifuge consists of a main channel (1), in which the model is built or placed, and a tool platform (2), where actuators and sensors can be mounted together with the data acquisition systems. With a diameter of 2.2 m, 0.7 m height and 0.3 m depth, the channel can be accelerated up to 440g carrying a payload of up to 2 tons. A key advantage of the drum centrifuge is that the entire channel can be filled with soil, creating a model deposit of 5 m length, which corresponds to a prototype of 2 km length, over 100 m depth and 300 m width. Smaller models can be tested using strongboxes, prepared outside and placed on the channel.

The rotation of the channel and the tool platform is provided by an external (4) and an internal (5) shaft, respectively. The tool platform can spin together with the channel, or independently. This allows stopping the tool platform during a test, allowing changes or adjustments of actuators and sensors mounted on the platform without stopping the test. In such a case, a shield is lowered to protect the stationary platform from the spinning channel. Communication between the on-board computer and the control room is provided by sets of electrical slip rings (6, 10, and 13). An additional slip ring is mounted on the tool platform over the internal shaft (5), allowing supply of water to the spinning model from an external source.

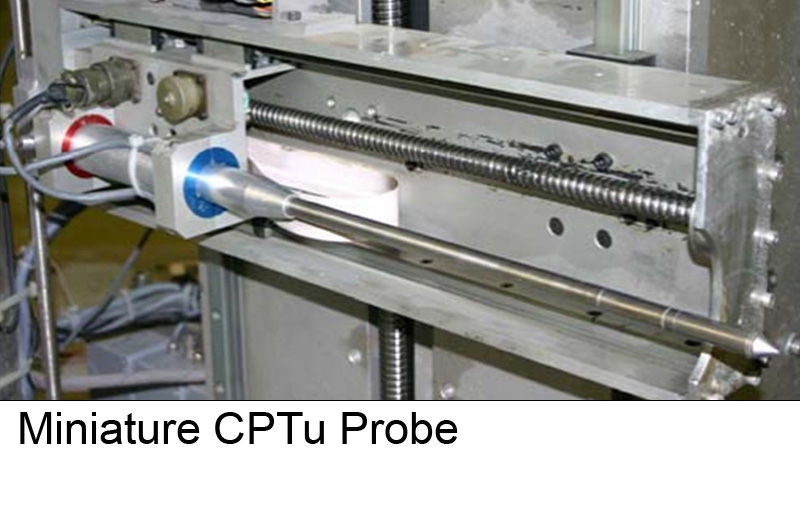

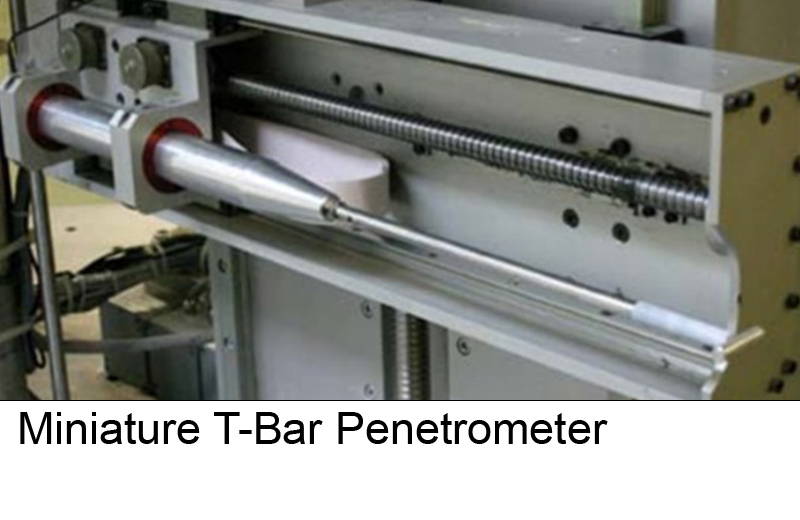

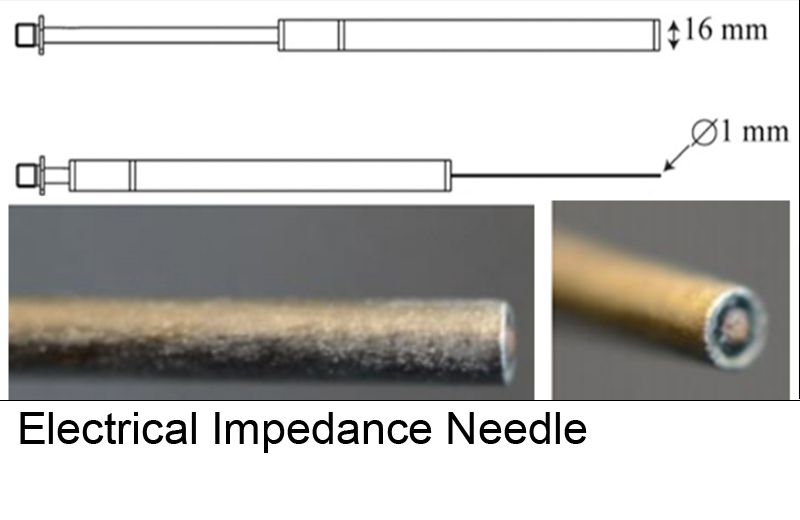

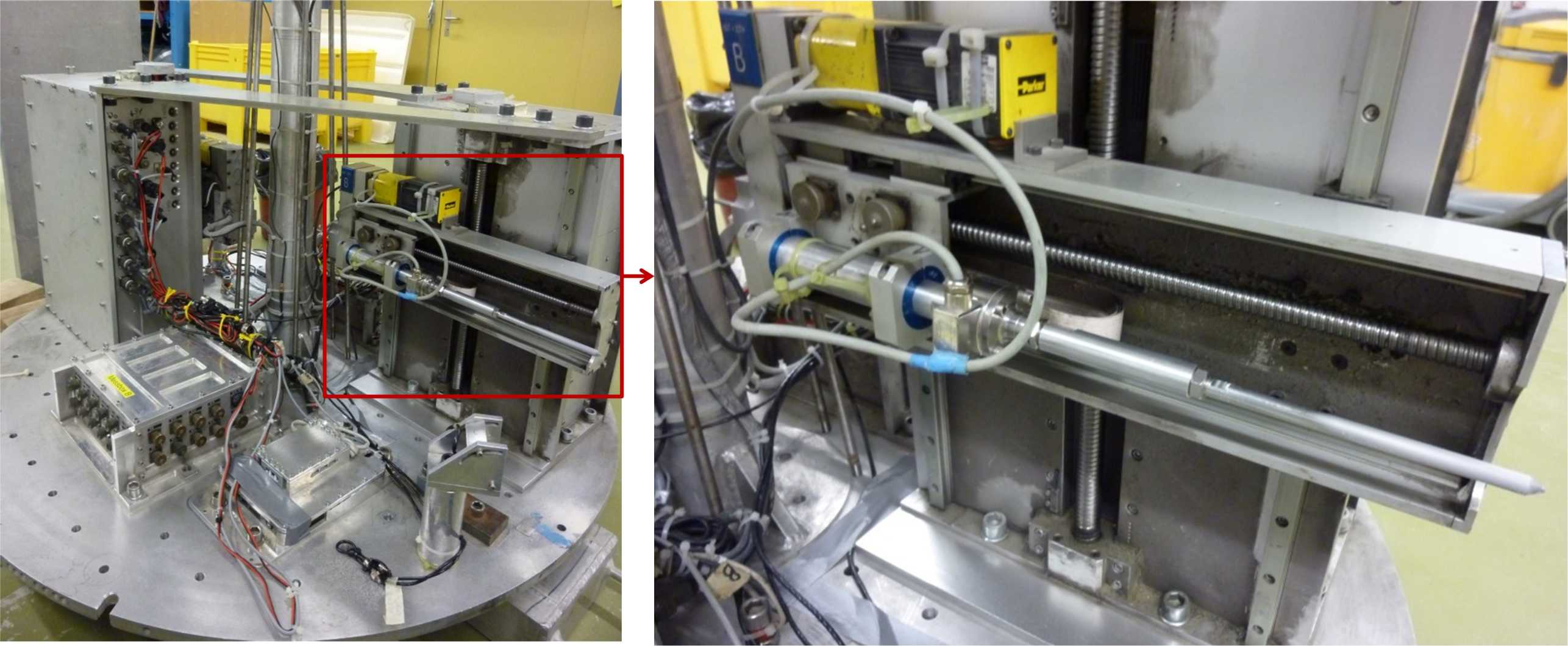

Besides the data acquisition system and the on-board computer, the tool platform is equipped with vertical and horizontal servo-electric actuators. In combination with the ability of the platform to rotate independently from the drum channel, the system allows actuation in 3 degrees of freedom (vertical, horizontal, and lateral). The actuators are equipped with load cells and laser displacement transducers to control and measure the results of the test. Depending on the specific needs of the test, different tool platforms are available, containing other types of actuators and instruments.

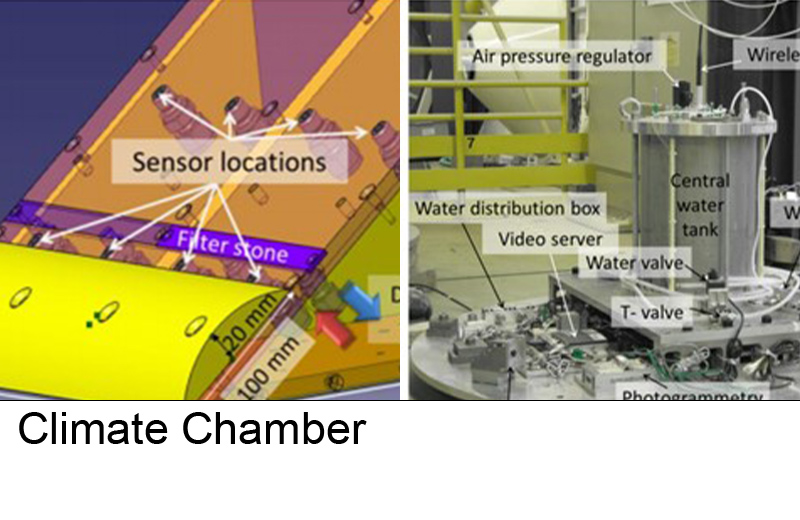

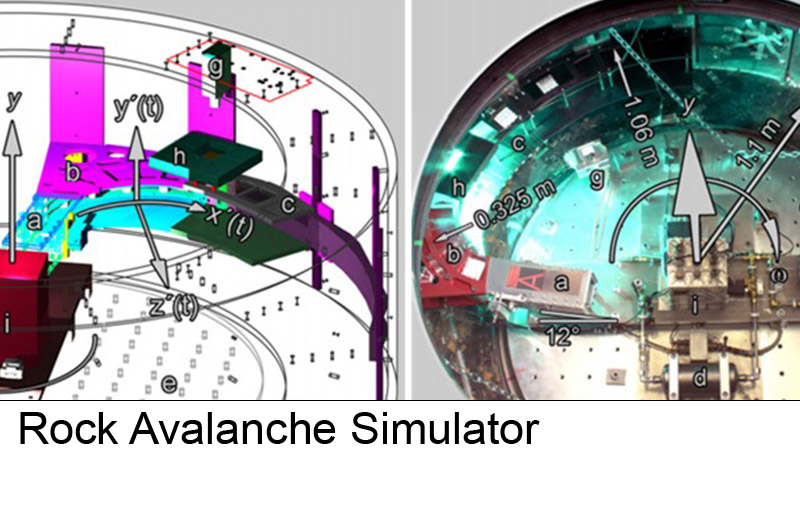

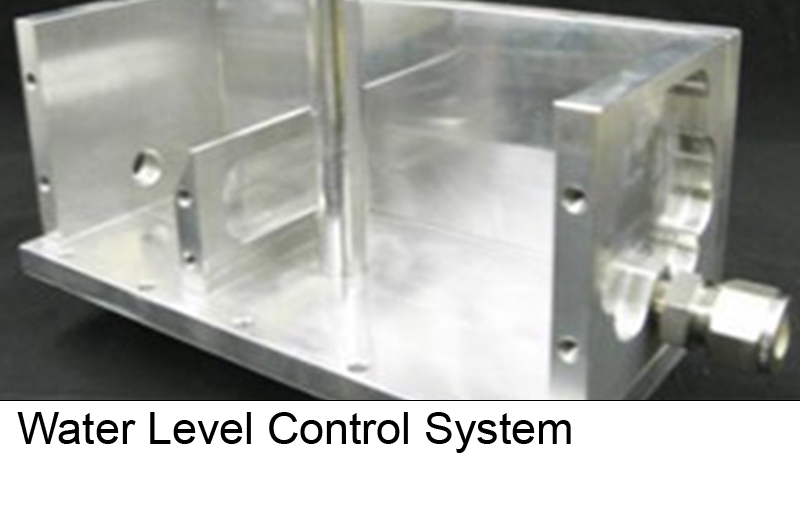

Click on the images below to explore each subcategory